Project Description

Description

Type HS pumps are horizontal, centrifugal slurry pump, which are commonly used for long distance transport lines. The HS pumps can often satisfy application duties with a single pump where others require multiple pumps.

Features

- High efficiency, wear resistant, stable performance, interchangeability of parts; high head; energy saving.

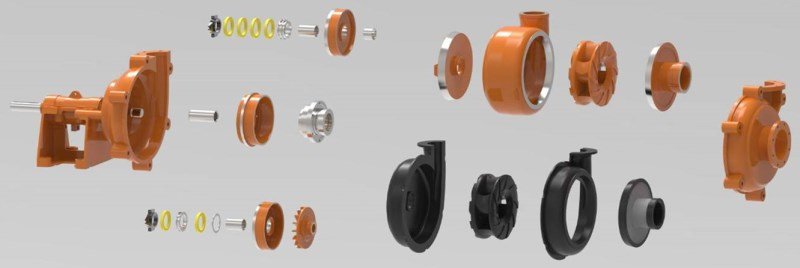

- Replaceable wear-resistant metal liners, impellers&volute liners are made of wear-resistant metal(such as L05,L49,L61, and other high chrome metal or rubber). The bearing layer and the wear-resistant layer can be separated.

- High efficiency impeller of large diameter and slow rotation speed ensures the pump with long wear parts using life and low operating cost.

- Bearing assembly use cylindrical structure, adjusting the space between impeller& front liner easily, being removed completely when being repaired. Grease lubrication.

- Shaft seal could use the packing seal, expeller seal and mechanical seal. One pump also can be use packing seal with expeller seal together.

- The discharge outlet can be positioned to 8 directions at intervals of 45 degrees.

- This pump can be installed in multistage series to meet the delivery for long distance.

- Drive types: direct coupling drive(DC), V belt drive(CR, CV, ZV, CL), etc.

Typical Application

- Iron Ore Dressing Plant

- Copper Concentration Plant

- Gold Mine Concentration Plant

- Potash Fertilizer Plant

- Other Mineral Processing Plants

- Alumina Industry

- Coal Washery

- Power Plant

- Other industries

Technical Parameters

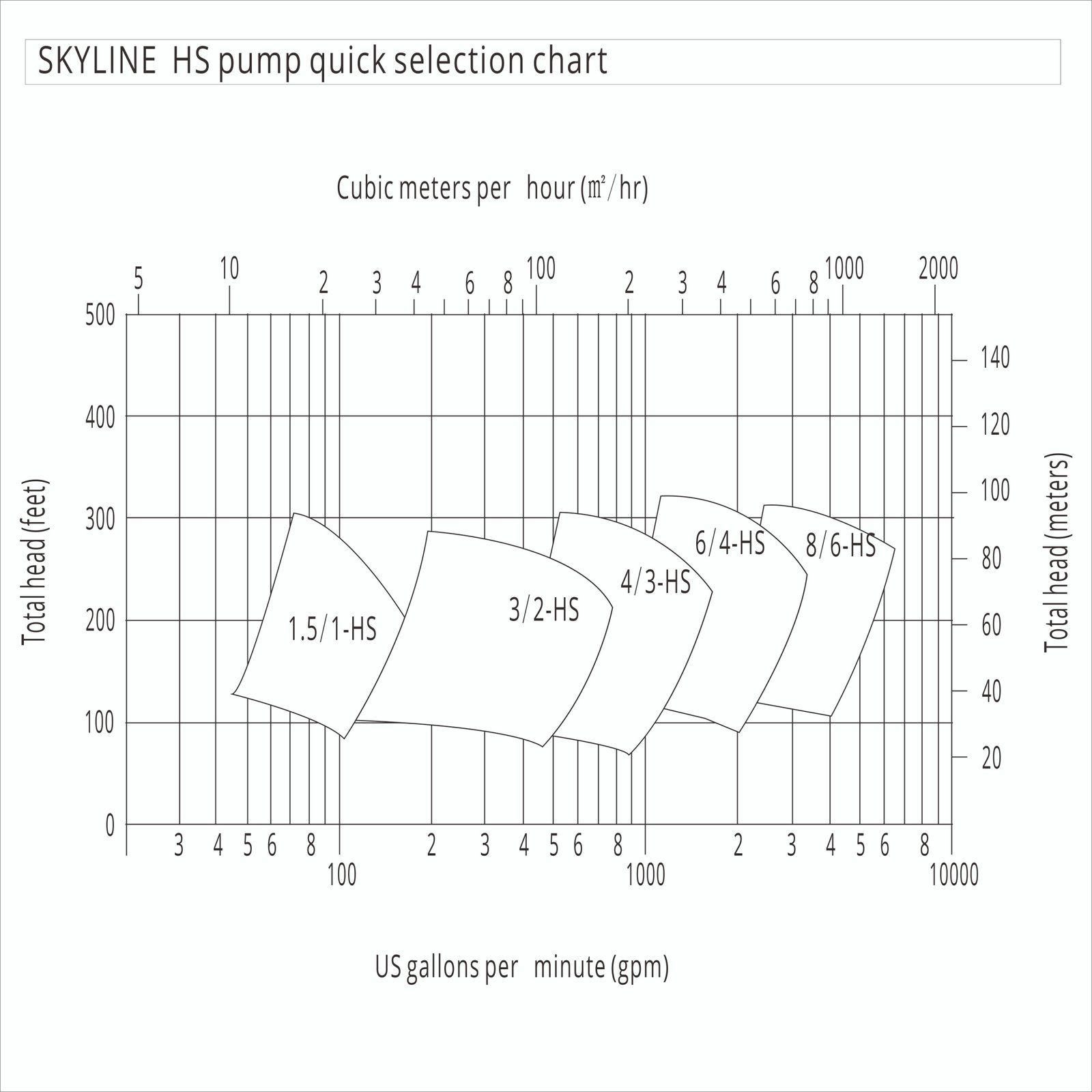

Size:1’’-18’’(25-450mm)

Flow Rate:16-1125m³/h

Total head:12-95m